Special Projects

In a diversified field with a wide range of essential variables, McNolty has become a leader in developing and implementing definitive, approved, specialized techniques to deliver the highest quality products and services.

X-Ray Inspection

Military

With less than desirable environmental circumstances, McNolty performed an installation of a double wall Jet Fuel containment system with the highest level of Quality inspections allowed at the Canadian Forces Base Trenton, Ontario. In all, 3000 linear feet of pipeline was installed with 100% radiographic (x-ray) inspections performed for every single weld joint. We met and exceeded quality expectation, scheduling and completion dates.

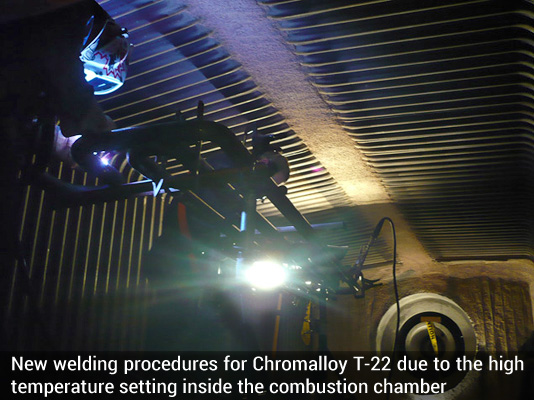

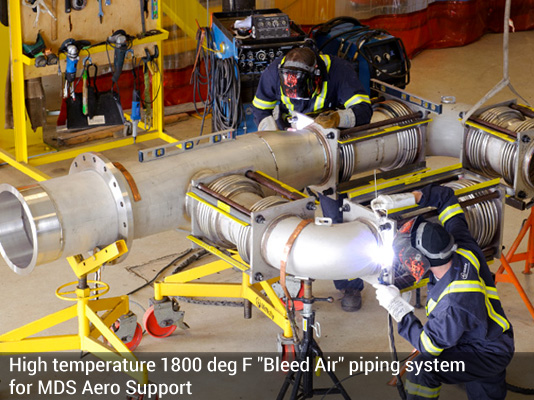

Aeronautics

Working hand in hand with MDS Aero Support, McNolty developed new welding and machining techniques for the manufacture of Venture Nozzles used for testing and calibrating emissions for Jet Turbine research. All Aluminum components were heat treated and hardened from a T-0 to a T-6. State of the art welding equipment with intercoolers were used to create ultra-pure welds. All welds were x-rayed (radiographed) to B31-3 standard.

Working hand in hand with MDS Aero Support, McNolty developed new welding and machining techniques for the manufacture of Venture Nozzles used for testing and calibrating emissions for Jet Turbine research. All Aluminum components were heat treated and hardened from a T-0 to a T-6. State of the art welding equipment with intercoolers were used to create ultra-pure welds. All welds were x-rayed (radiographed) to B31-3 standard.