Industrial Maintenance

McNolty has consistently shown leadership in an industrial market place by providing technical experience, knowledge and power production to its clients.

The Challenge

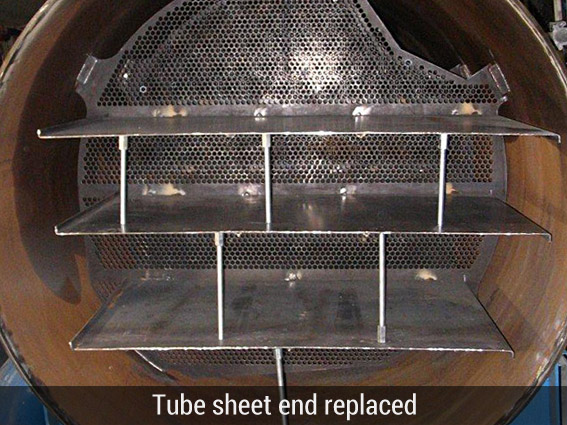

Refurbishment of an 8500 Ton York OM Steam Turbine Driven Chilled Water Condenser at Cliff CHCP Power Plant for the Canadian Government.

The Solution

McNolty coordinated and completed the full renewal of the condenser tube supports, tube sheet end along with replacement of discharge baffling plates, from beginning to end. This required precision welding, fit up and alignment for 9 discharge baffling sheets each containing 4400 ports for rolled and flared copper exchange tubes.

McNolty was successful in reaching every time critical benchmark and completing ahead of schedule.

Power Plants

Industrial power generation plants have become more complex and exceedingly detailed in part due to modern mechanical engineering, innovative approaches to energy production as well as minimizing consumption. The emphasis of maintaining energy producing facilities is of utmost importance as clients mandate efficiency and environmentally friendly means of production

Timelines

Industrial maintenance is only successful if strict “shut down” timelines are completed, and deliverable targets are met. McNolty works hand in hand with this specific client base, overcoming these challenges and delivering workable solutions

Experience

Diversity and flexibility are vital to our success with the knowledge that even the best-laid plans need experienced adjustments to achieve successful completion.

Performance

By consistently meeting the complex and time sensitive requirements of these projects, McNolty has always been an invaluable resource for these installations.